GMT has worked with leading science and institutional organizations worldwide. Our products can be found in hospitals, a Keck Array telescope installation in Antarctica, 4,500 meters deep in the manned submersible Alvin, and in the test labs of MIT. GMT is an agile company. We quickly understand a customer's needs, and we have the engineering expertise and manufacturing experience to develop ideas. We can then rapidly and inexpensively turn out prototype or production parts.

Example Projects

aSTRONOMY

The Smithsonian Astrophysical Observatory (SAO) named GMT as "the best outside contractor working on the project" during development of their submillimeter array, located on Hawaii's Mauna Kea volcano. GMT was asked to build the frames for the 6-meter dishes. These quadrupod structures stand twelve feet tall and hold the focusing mirror sensors. Even the system’s name, a submillimeter array, gives evidence of the precision required in fabrication.

The summit region of Mauna Kea where the array is located is subjected to extreme environmental conditions. The antennas had to be exceptionally rigid and stable, even when buffeted by mountaintop winds, scoured by volcanic ash, and subjected to wide temperature fluctuations. The assemblies and their enclosures also had to be repositionable in an hour, being picked up and moved over steep unpaved roads.

The lightweight and rigid nature of carbon made it an obvious choice, and GMT's expertise in manufacturing made us well suited for the challenge.

Image credit: Woods Hole Oceanographic Institution

UNDERSEA

GMT has worked with a number of organizations to provide lightweight carbon solutions for a range of undersea projects. Ballast tanks for the renowned research submersible Alvin, fairing covers for submarine masts, and parts for mini-subs and foils for towed vehicles are among the many things GMT has produced.

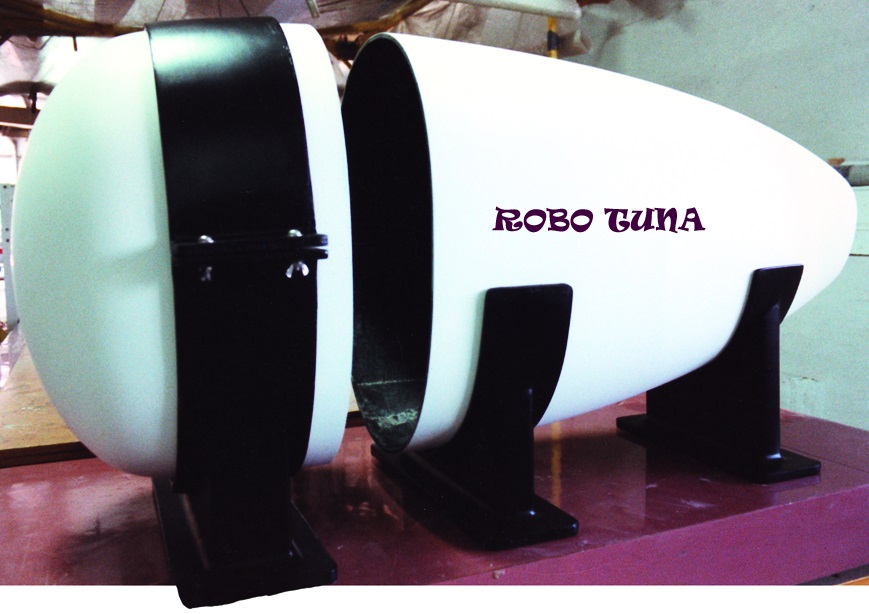

One intriguing project was for Draper Laboratories, who was investigating an alternate propulsion system based on the way fish swim. GMT provided the fish body which was very accurately modeled after the body of a tuna. Draper developed a very sophisticated tail, actuator, and electronic control system to mate with this body. The hope is that the work will result in a highly energy efficient means of propelling underwater vehicles.

When Wood's Hole Oceanographic Institution (WHOI) decided to complete a major refit on their submersible Alvin, GMT was selected to build three very complex ballast tanks that had to fit around the structure of the vessel due to limited space. The goal of the refit was to upgrade Alvin's depth rating from 4,500 meters to 6,500 meters, where pressures can exceed 5 tons per square inch. Under that kind of pressure, any air void content would get crushed. GMT was honored to be a part of the project, and this sort of work is what sets GMT apart from the competition.

MEDICAL

The radiolucency and dimensional stability of GMT carbon composite structures makes them very suitable for use in advanced medical scanning equipment. The minimal scatter in beams passing through the material sharpens imaging and reduces damage to non-targeted tissues while the rigid positioning pieces permit precision in targeting and more accurate repeatability. It gives us a special sense of satisfaction to be able to apply these talents to medical devices that are helping to save lives. If you have a medical system that might benefit from the unique properties of composite parts, please contact us so we can discuss solutions.