For over thirty years, GMT has been building rudders for customers who demand the best. Carbon composite rudders and stocks were among the first products engineered and built by GMT, and over the years GMT has built a huge variety of rudders for both racing and cruising yachts of all sizes. A carbon composite rudder and stock offers a strong, lightweight and durable solution with a range of benefits. By removing weight from the stern you increase the safety factor of the vessel’s steering system as well as overall performance. Also, carbon does not corrode in a saltwater environment, so there is no fear of pitting or degradation of the rudder post.

The engineering, materials, and construction methods that are used at GMT to build every rudder are unsurpassed. Having built rudders for America's Cup syndicates, offshore ocean racers, and a variety of large cruising yachts, you can rely on our rudders to perform and deliver you safely to your destination.

engineering and testing

Our in-house staff of mechanical engineers uses computer programs developed at GMT to design your rudder. All posts, except those for special applications like America's Cup boats, are designed to exceed American Bureau of Shipping standards.

Since there are no published standards for the strength of composites, GMT has done extensive testing on different laminates that we have manufactured. This accurate information on the actual strength of the material allows our engineers to design very strong, light parts that will stand up to the rigors of rough weather.

Post & Blade Materials

Carbon rudder posts can be made from many different types of material. We use the best: carbon that has been pre-impregnated with epoxy resin. With this process, our supplier uses sophisticated equipment to coat uni-directional carbon with a very precise amount of resin. Our technicians apply layers of this material to the post tool. When the specified laminate is constructed, the post is cured under pressure in our 250 degree oven. Although the pre-preg process is more costly than the process of mixing resin and carbon in a shop, it is much more controlled. With pre-preg, we can build parts that are uniform throughout, and won't fail.

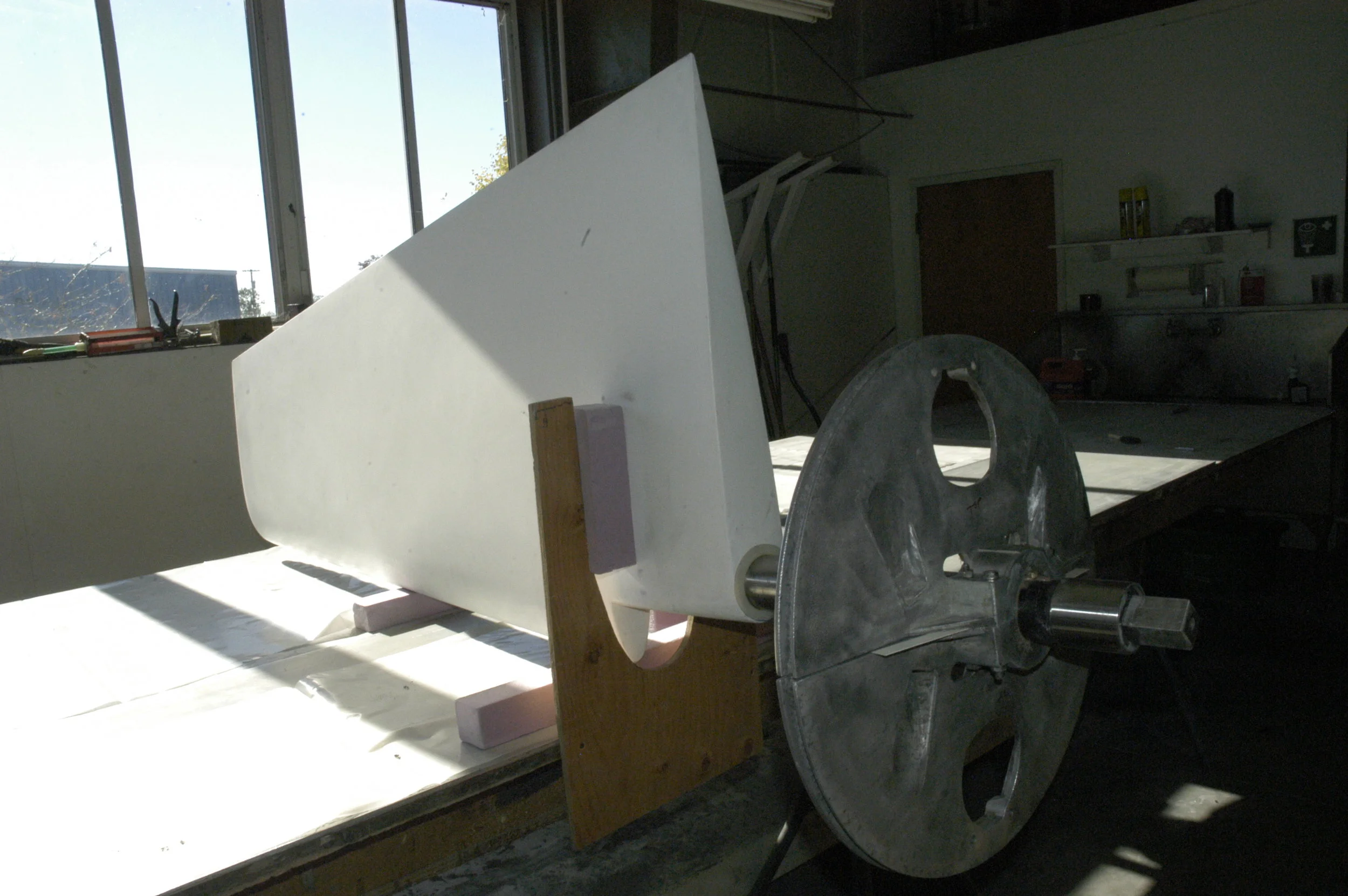

Our rudder blades start with a rigid, closed cell, foam. The foam is highly cross-linked to give it excellent strength and stability. It is a material that has been approved by organizations like American Bureau of Shipping, Lloyd's and Det Norske Veritas. In the lightest rudders, honeycomb core is used. The stability of these core materials means that the precise shape we build into the rudder will be the shape you'll be sailing with for years to come. For the rudder skins, we use uni-directional carbon. This material takes more time to apply than woven carbon cloth, but is much stronger. We also use a layer of woven fiberglass on the outside to improve impact and abrasion resistance.

rudder shape

The airfoil shape of a rudder is critical. The blade must be symmetrical about the vertical center plane. If it is not, the boat will steer differently on port and starboard tack. The finished shape of the rudder must exactly conform to what the architect designed or it will slow the boat down and cause excessive leeway. At GMT we start by drawing the airfoil shapes along the span of the blade using AutoCAD, a computerized drawing system. The blade is then faired along its length by another program using three dimensional spine curve-fitting techniques. All this information is then down loaded into our computer controlled milling machine. The operator can then stand back and watch the CAM machine carve a perfectly shaped blade.

finish

We take extra care to finish our rudders to a high level of smoothness. After coating with a two part epoxy paint, the rudder is wet sanded. This takes time but improves the rudder. If you dry sail the boat, you are ready to go. You can also apply any bottom paint directly over this epoxy surface.

the bottom line

Quality and care in materials, engineering and workmanship result in a superior product. Of the hundreds of composite rudders that we have manufactured, over 99% have withstood all the stresses the sea has put them through. Our rudders have steered boats that have won the America's Cup, Maxi Championship, ULDB 70 Championship, IOR 50 Championship Around Alone Race and many more world class events. They have been around the world on long distance cruising boats from 40 to 140 feet. Whether you are concerned about arriving safely at your destination after an ocean passage or first at the finish line after a day race, a rudder from GMT is clearly the way to go.